Case Davy Crockett Bowie 1836 – Restored

BRAND: Case

PATTERN: Bowie Knife

BLADE ETCH: Mark Side: Davy Crockett with coonskin & Bowie knife etched near front of the blade.

BLADE ETCH: Pile Side: ORVET CUSTOMS (logo)/ DALE VINCENT

OAL: 15”

BLADE LENGTH: 9”

GUARD: Brass

HANDLE: Elk Stag

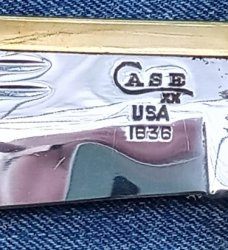

TANG STAMPS: CASE/XX/USA/1836 (Long Tail C)

SHEATH: No sheath comes with heavy nylon case that is padded and lined.

BLADE WEAR: I don’t think this blade had ever been sharpened until I sharpened it.

AGE: Circa 1965 to 1969

MADE IN: U.S.A.

CUSTOMIZED IN: U.S.A. by Orvet (Dale Vincent)

ADDITIONAL INFO: This knife is in nice shape considering its age. There were a few little dings in the blade that I had to sharpen out, but I it had ever been sharpened. The black composition handle on this knife was split and broken and held together with tape when I got it. There are a few dings in the brass back and in the guard. The guard was modified to an S-shape before I got the knife. Originally both quillons were straight, as the design is based on the design of the always made by Collins for the M592 bailout bags for pilots and aircrew men. Case and Kinfolk also base their aircrew knives on Collins design. Like the original World War II version this knife also has the double narrow fuller as did the original Collins design.

The purpose of the brass bar on the back of the blade is to catch your opponent’s blade so that it doesn't slide down and get your hand. It is also used for trapping your opponent’s blade between the brass bar and the guard thus using leverage twist his blade from his hand, thus disarming him. The fact that his blade tends to bite into the brass bar and doesn’t allow it to slip makes it easier for you to twist his blade out of his hand, especially if he’s not an accomplished knife fighter.

It is also been suggested that the brass bar it helps soften the blow from another blade to prevent an inferior quality blade from snapping. Both the guard and the brass bar have dings on them. They don't seem to be deep, almost like they were put there for affect. The dings in the brass do seem to add character to this old knife. There are a few light scratches on the blade but they aren't highly visible and even when seen add to the knife's character.

The replacement handle on this is made from genuine elk antler. I have quite a bit of elk antler but finding the exact right piece to make into a handle is always difficult. There is usually a twister or bend that is not quite right, it is too thick or too thin or just not quite right. There are many factors to consider when trying to use a piece of natural antler with minimal modification to make a knife handle.

I spent most of the year looking at the knife and the antler I had, even buying more antler but went back to an older piece when I found just the right fork in a beam. The fork in the antler provided a nice downward turn like the original handle, to help lock in your grip without allowing your hand to slip. The finger grooves I put in the bottom of the handle are not very deep, but I was amazed at the additional grip and control of the blade they provided. The handle is held on the tang by two methods: epoxy, and mechanical pins. The epoxy is a strong epoxy I have used for years and have great confidence in its strength. There are three brass pins going through the tang and through the antler that are hand peened.

At the end of the handle, where the larger fork of the antler was removed, I rounded it off and smoothed it down so there are no sharp edges and in that surface. I then inlaid a shield in the shape of the state of Oregon which I frequently use on customized folders. The ends of the exposed antler are sealed with multiple (dozens) of coats of cyanoacrylate glue. Starting with thin CA that penetrates deeply into the porous center of the antler and then finished with heavier CA glue. After the center of the antler was hardened, I begin the process of polishing the cut ends. This involved alternating coats of CA, allowing it to dry and then sanding down smooth. I repeated the process as often as necessary until I felt it was as smooth as I could get it and then I changed to a finer sandpaper and begin the process again. There were more coats of CA with the coarser grits of sandpaper than there were between the finer grits of sandpaper.

I could not make a sheath for this knife because the arthritis in my hands would prohibit the hand sewing. It does come with a nice padded fuzzy lined nylon Cordura type zipper case. If you need more pictures, please let me know I would be happy to send some to you.

For those who enjoy watching a knife in restoration, the last two pictures I am including in this listing are the knife as it was when I started on it. I had removed the layers of electrical tape from the handle and I had cleaned the blade off somewhat before I took those pictures.

*By Purchasing, The Buyer Confirms It Is Legal for Them Purchase and Own This Knife.

I Accept Money Orders, Personal Checks and PayPal.

Shipped by Priority Mail in the US.

Item # 46258

Sold

Check Out More Great Products Related To This One!!!

Greg Wall Custom Crane Style Hollow Handle Survival Knife And Sheath NEW

1 In Stock

$450.00

For Sale By:

awrjrr

Todd Davison Mammoth Sheepsfoot Straight Jack...3 5/8"..Cpm154..coinedged...pouch...#2535 Rare

1 In Stock

$950.00 $1,059.99

For Sale By:

3FingerMac

Rare 4 1/4" Custom Handmade Double Bird's Head Bolster Knife with Beautiful Stag Handles

1 In Stock

$187.50

For Sale By:

Eight Knives

4 3/4" Custom Handmade 2-Blade Gunstock Knife with Premium Stag, Filework

1 In Stock

$187.50

For Sale By:

Eight Knives

5 1/8" Custom Handmade Trapper Knife with Bird's Head Bolster, Imitation Amber Handles, File work

1 In Stock

$197.50

For Sale By:

Eight Knives

Fightin Bull-USA Wendell Carson Warthog Ivory Gunstock Model # 2640

1 In Stock

$275.00

For Sale By:

Kennedy Knives

Mickey Yurco Self Defense 440C Mint #676 Layered Wood Hand Made Sheath By Erickson

1 In Stock

$169.50

For Sale By:

Scagel

Mickey Yurco Self Defense 440C Mint #621 Layered Wood Handles Custom Sheath By The Maker

1 In Stock

$169.50

For Sale By:

Scagel

Vincenzo Balistreri MOP Marea Slipjoint.3.75"..Timascus..interior lanyard pin..filework..coa.. slip

1 In Stock

$650.00 $749.99

For Sale By:

3FingerMac

BEAUTIFUL CUSTOM HANDMADE POCKET FOLDING KNIFE LOCK BLADE and TIE PIN MATCHING T IN SHIELD MARK

1 In Stock

$185.00

For Sale By:

awrjrr

JM, HANDMADE EBONY & DAMASCUS SLIP JOINT PISTOL GRIP FOLDING KNIFE

1 In Stock

$125.00

For Sale By:

awrjrr

Custom B W Smith & Sons Stag 2 Blade Folding Hunter Pattern Knife

1 In Stock

$175.00

For Sale By:

awrjrr

Todd Davison Abalone Sheepsfoot Straight Jack...3 5/8"..Cpm154..coinedged...pouch...#2431 Rare

1 In Stock

$950.00 $1,059.99

For Sale By:

3FingerMac

K'roo Fancy Jack in Ivory Paper..Black Diamond shield and liners...Ringed Fancy bolsters and caps

1 In Stock

$450.00 $529.99

For Sale By:

3FingerMac

K'roo Executive Jack Wharnie Chaos..Rwl34...Equal End...Bolsters and caps...fileworked..Coa and slip

1 In Stock

$625.00 $699.99

For Sale By:

3FingerMac

Kroo MOP Sheepsfoot Fancy Jack.. Rwl34..3.75..fluted..filework..spacers..liners..coa/slip

1 In Stock

$600.00 $649.99

For Sale By:

3FingerMac

Mike 'Whiskers' Allen And Linda Karst 4 1/4" Closed Big Cat Skrim Buffalo Handles File Work Engraved

1 In Stock

$294.50

For Sale By:

Scagel

K'roo MAC Knife..Sheepsfoot..3.5"..Black Linen bolsters&caps..Warthog Tusk Ivory Scales..Damasteel

1 In Stock

$600.00 $699.99

For Sale By:

3FingerMac

A.A. Al Sanders Norman OK 3 7/8" Closed File Work Mirror Polished Bone handle Engraved Bolstes

1 In Stock

$589.00

For Sale By:

Scagel

P.A.K. Martin J. Patterson Custom Fixed Blade Knife – Seward, Alaska with Sheath

1 In Stock

$199.00

For Sale By:

Steph's Knives

Vintage 16 1/2 inch Balisong Balisword from the Phillipines With Eagle Head

1 In Stock

$500.00

For Sale By:

Rubens Blades

Vintage 32 inch Balisong Balisword from the Phillipines With Eagle Head

1 In Stock

$1,000.00

For Sale By:

Rubens Blades

Sheldon Jones Custom Fixed Blade Knife – Crown Stag– Trained Under Bill Moran

1 In Stock

$275.00

For Sale By:

Steph's Knives

Sheldon Jones Custom Fixed Blade Knife with Sheath – Trained Under Bill Moran

1 In Stock

$225.00

For Sale By:

Steph's Knives

Custom 11 Inch Ring Pull by Rubens Blades in Collaboration With Dolphins Knives

1 In Stock

$500.00

For Sale By:

Rubens Blades

Custom 11 Inch Ring Pull by Rubens Blades in Collaboration With Dolphins Knives

1 In Stock

$500.00

For Sale By:

Rubens Blades

Custom 11 Inch Ring Pull by Rubens Blades in Collaboration With Dolphins Knives

1 In Stock

$500.00

For Sale By:

Rubens Blades

Custom 11 Inch Ring Pull by Rubens Blades in Collaboration With Dolphins Knives

1 In Stock

$500.00

For Sale By:

Rubens Blades

Vintage William "Bill" Stoddart Custom Fixed Blade Knife and Leather Sheath

1 In Stock

$249.00

For Sale By:

Steph's Knives

Custom Ray Beers Fixed Blade Knife – Buffalo Horn Handle – Rare Find! With Sheath

1 In Stock

$595.00

For Sale By:

Steph's Knives

CUSTOMIZED CHALLENGE CUTLERY CORP. WHITTLER CHECK OR MONEY ORDER

1 In Stock

$125.00

For Sale By:

jerdan

Kroo Warthog Tusk Ivory Sheepsfoot Barlow.. Rwl34..3.75..fluted..filework..spacers..liners..coa/slip

1 In Stock

$650.00 $699.99

For Sale By:

3FingerMac

K'roo Slimline Wharnie"...4"...Black Linen bolsters&caps..Warthog Tusk Ivory Scales....Damasteel

1 In Stock

$600.00 $699.99

For Sale By:

3FingerMac

Custom 11 Inch Stabilized Lacewood Shark Lockback By Dolphins Maniago Italy

1 In Stock

$235.00

For Sale By:

Rubens Blades