Got a Question about your bench anvil....

Got a Question about your bench anvil....

I've got someone making a bench steady (Cutler's steddy, or any of the other names they've been called). I'm hoping we can keep this topic going for a while so I can post pictures of it on this thread when it's finished.

BUT.....

For now, I'm just curious what kind of small anvil do YOU have on your workbench for working on knives? I'll follow up with pictures, I promise! But I think it would be intersting to see what everyone had come up with.

BUT.....

For now, I'm just curious what kind of small anvil do YOU have on your workbench for working on knives? I'll follow up with pictures, I promise! But I think it would be intersting to see what everyone had come up with.

Re: Got a Question about your bench anvil....

Good thread, Elvis.

I hope you get some good responces. I don't use a steddy, but I think they are a neat tool, what little I've seen of them on here. Actually, I"d like to do work on pocket knives, but I sure can't now.

I hope you get some good responces. I don't use a steddy, but I think they are a neat tool, what little I've seen of them on here. Actually, I"d like to do work on pocket knives, but I sure can't now.

Joe

Re: Got a Question about your bench anvil....

I bought my first steady. By the time I paid shipping I paid nearly $300 for it.

Since then I have come up with a much less expensive alternative. I make them.

I have sold several in my AAPK store, though I don't have any completed currently, though I do have one or two in the works.

I will get some pics and post them later.

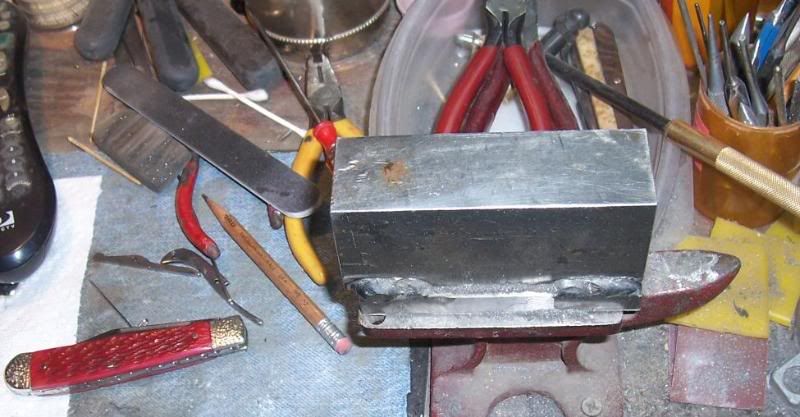

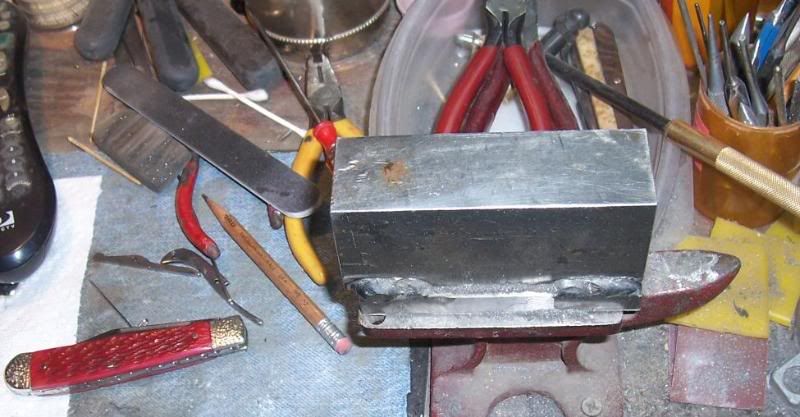

Here are pics of some stiddys I have made in the past.

Since then I have come up with a much less expensive alternative. I make them.

I have sold several in my AAPK store, though I don't have any completed currently, though I do have one or two in the works.

I will get some pics and post them later.

Here are pics of some stiddys I have made in the past.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

Re: Got a Question about your bench anvil....

Is that made from a piece of I beam, Dale?

What is the height?

What is the width of the base?

..... Joe

What is the height?

What is the width of the base?

..... Joe

I've got a camouflage knife, but I can't find it.......

..... cardboard addicted.....

"The old timer's concentrated on making knives; not keeping records!!" ~ Bonfire bob

..... cardboard addicted.....

"The old timer's concentrated on making knives; not keeping records!!" ~ Bonfire bob

Re: Got a Question about your bench anvil....

looks like early narrow gauge rail stock...mining use maybe.

Re: Got a Question about your bench anvil....

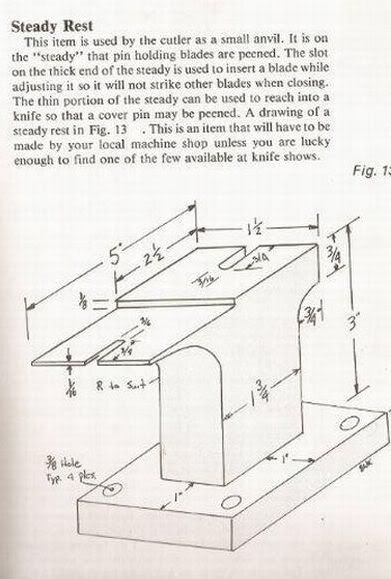

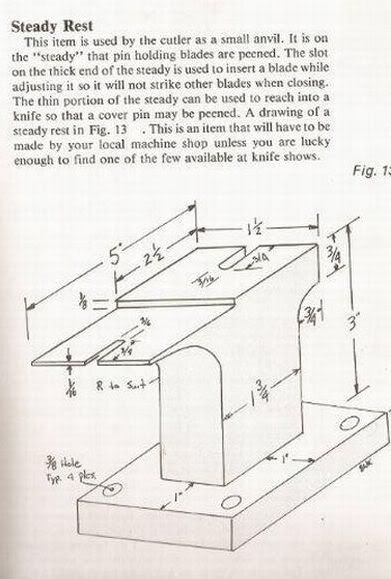

I don't have one yet, been using some old body work tools, but found a interesting pic on the net. Should enlarge.

Re: Got a Question about your bench anvil....

Now THOSE are some nice looking stiddies Gary!!

Are these for sale or do you know? I didn't know from your post if you just seen a pic or found some that were for sale.

I also have a pic laying around here somewhere of a very nicely made stiddy. I can't remember where I copied it from, but it came from the net. If I can find it, I will post.

Are these for sale or do you know? I didn't know from your post if you just seen a pic or found some that were for sale.

I also have a pic laying around here somewhere of a very nicely made stiddy. I can't remember where I copied it from, but it came from the net. If I can find it, I will post.

Re: Got a Question about your bench anvil....

No I don't believe these are for sale, just pics from British Blades forum, I' planing on making one, just trying to figure out what style, and features will best suit my needs. Or if one comes up that's reasonably priced, I would consider it, but right now I don't think that can happen.

Re: Got a Question about your bench anvil....

Gary I did find the copies I had run and most of them DID come from bladeforum. The fit and finish on the ones I copied is smooth as silk. It seems that every line runs into another.......like a flow, I guess. I had written down that Great Lakes Water Jet was either making them or going to start making them. I went to their website (unless there is more than one) but didn't see any. When I piddle with knives, I've got my own home made crap that I get by on. When I win the lottery, I've got a stiddy on the list!

Re: Got a Question about your bench anvil....

I am so with you on the home-made crap. It's how I've been getting by for years. I've got some pictures that I hope to explain and a diagram scanned in from a book that is being used to fashion the bench anvil that I'm told will be delivered TOMORROW! (YES, I'm a tad excited about it!) Let's start with the pics: (NOTE: one pic is just a block of very hard wood with a couple of holes in it. (Cumaru-S.American Chestnut) I use it for an anvil most times when I drive a pin out of a nickel-silver bolster to avoid scratching it.)

As you can see, one picture is simply a couple of small anvils from Harbor Freight with a few pieces of hardened metal in the plastic box with them. A quick trip to the welding shop and my friend can put these together in any number of configurations and then the rest is up to me and a cutting wheel and grinder. Another is of the small hammers I use for peening. Yes, they're small and I really think that it helps a lot when peening nickel-silver expecially on MOP. Light tapping helps heat up the metal while working it and makes it bend into shape easier (my opinion). The other pieces are blocks of steel begged from my friendly welding shop with some welded together and finally is the last picture which is a scan of the one I'm having made. These dimensions were fed into some huge computerized CNC machine and it has been making the piece from a large chunk of A4, which I'm told is a tool steel. I should be able to show pictures of it soon.

And while I'm still typing....Dale, Sweet work on the home-made jobs! I really like the sharp point on the anvil head (I can picture many handy occasions) and the add on is brilliant. Gary...Great pictures! That's what I'm talking about. Those were probably putting knives together a century ago. Too cool!

As you can see, one picture is simply a couple of small anvils from Harbor Freight with a few pieces of hardened metal in the plastic box with them. A quick trip to the welding shop and my friend can put these together in any number of configurations and then the rest is up to me and a cutting wheel and grinder. Another is of the small hammers I use for peening. Yes, they're small and I really think that it helps a lot when peening nickel-silver expecially on MOP. Light tapping helps heat up the metal while working it and makes it bend into shape easier (my opinion). The other pieces are blocks of steel begged from my friendly welding shop with some welded together and finally is the last picture which is a scan of the one I'm having made. These dimensions were fed into some huge computerized CNC machine and it has been making the piece from a large chunk of A4, which I'm told is a tool steel. I should be able to show pictures of it soon.

And while I'm still typing....Dale, Sweet work on the home-made jobs! I really like the sharp point on the anvil head (I can picture many handy occasions) and the add on is brilliant. Gary...Great pictures! That's what I'm talking about. Those were probably putting knives together a century ago. Too cool!

Re: Got a Question about your bench anvil....

By the way.....If anyone knows a lot about A4 tool steel, please share a bit. I don't need a college degree, just opinions on how you all think it'll work as a bench anvil. Thanks!

Re: Got a Question about your bench anvil....

I am down with the homemade stuff as well!

I did buy my first steady several years ago and it cost me nearly $300 by the time I paid shipping. If I knew then what I know now I would not have spent that much money.

It works very well. The aluminum disc is what I use to peen down the inside scale pins. The aluminum is soft enough that the pin will dent the aluminum and won’t flatten out the head I have spun on it. But it gives enough resistance to flatten out the little bit of pin on the inside of the liners.

A year or so after I got the first stiddy I was corresponding with some of the guys who had worked at Camillus. One of them (I don’t recall which one at the moment, but I think it was Tom Williams) sent me one of the original stiddys that they used at Camillus. As you can see it looks a lot different than the manufactured one. It sits in a socket cut into the top of a workbench.

The Camillus stiddy got me to thinking that a useful stiddy didn’t have to look like the first one I bought. I already had a small anvil that someone had done a nice job of making from railroad track. It does not rebound like my Hay Buddon, but I wouldn’t want to forge on it anyway. I just use it when I need a hard surface to pound on in the shop.

This is the result of my first attempt at a stiddy. I welded the horn on a piece of railroad track. I didn’t have welding rod with manganese in it so the welds were pretty ugly & I am way out of practice with a cracker box. I sent this one to Johnnie Fain and he used it until he died in 2009. I think he had it for about 2 years. Johnnie couldn’t get around very well, so he did most of his knife work in his easy chair. He had a large plastic cutting board that he bolted the stiddy to and a small vise bolted onto it as well. Johnnie told me the stiddy really worked well. Annettee insisted on sending it back to me after Johnnie died, so now it sets in my bench and it is usually the first one I use.

The one I made for Johnnie is at the corner, the one to the left is the Camillus stiddy setting in the socket in the bench.

After welding the first stiddy I started attaching the horns with ¼” screws. The horn can be removed and replaced if a cutler decides they want to design a different horn. The top of the horn is offset from the top of the stiddy for use in crinking blades. They usually weigh about 4 to 7 lbs. depending on the gage of the track and the length of the stiddy. If you are a handy at all with a torch or have a good saw you could cut your own track and make your own stiddy just from looking at my design. I usually polish them up so they look pretty when they are new, but they don’t stay that way long when you start using them. The smaller ones I usually mount to a bench for better stability. If a guy cuts them at about 8” in length you probably wouldn’t need to screw them to a bench.

This is a picture of my stiddy/project table.

The tiny vise on the left corner is the one Johnnie had mounted to his cutting board.

He did some nice work setting in his easy chair.

If anyone is serious about building a stiddy, shoot me a PM & we can arrange to talk by phone.

It is easier to explain than to type it all out.

If you don't want to go to all the work, and it is considerable, you may be able to talk ma into building one.

Dale

I did buy my first steady several years ago and it cost me nearly $300 by the time I paid shipping. If I knew then what I know now I would not have spent that much money.

It works very well. The aluminum disc is what I use to peen down the inside scale pins. The aluminum is soft enough that the pin will dent the aluminum and won’t flatten out the head I have spun on it. But it gives enough resistance to flatten out the little bit of pin on the inside of the liners.

A year or so after I got the first stiddy I was corresponding with some of the guys who had worked at Camillus. One of them (I don’t recall which one at the moment, but I think it was Tom Williams) sent me one of the original stiddys that they used at Camillus. As you can see it looks a lot different than the manufactured one. It sits in a socket cut into the top of a workbench.

The Camillus stiddy got me to thinking that a useful stiddy didn’t have to look like the first one I bought. I already had a small anvil that someone had done a nice job of making from railroad track. It does not rebound like my Hay Buddon, but I wouldn’t want to forge on it anyway. I just use it when I need a hard surface to pound on in the shop.

This is the result of my first attempt at a stiddy. I welded the horn on a piece of railroad track. I didn’t have welding rod with manganese in it so the welds were pretty ugly & I am way out of practice with a cracker box. I sent this one to Johnnie Fain and he used it until he died in 2009. I think he had it for about 2 years. Johnnie couldn’t get around very well, so he did most of his knife work in his easy chair. He had a large plastic cutting board that he bolted the stiddy to and a small vise bolted onto it as well. Johnnie told me the stiddy really worked well. Annettee insisted on sending it back to me after Johnnie died, so now it sets in my bench and it is usually the first one I use.

The one I made for Johnnie is at the corner, the one to the left is the Camillus stiddy setting in the socket in the bench.

After welding the first stiddy I started attaching the horns with ¼” screws. The horn can be removed and replaced if a cutler decides they want to design a different horn. The top of the horn is offset from the top of the stiddy for use in crinking blades. They usually weigh about 4 to 7 lbs. depending on the gage of the track and the length of the stiddy. If you are a handy at all with a torch or have a good saw you could cut your own track and make your own stiddy just from looking at my design. I usually polish them up so they look pretty when they are new, but they don’t stay that way long when you start using them. The smaller ones I usually mount to a bench for better stability. If a guy cuts them at about 8” in length you probably wouldn’t need to screw them to a bench.

This is a picture of my stiddy/project table.

The tiny vise on the left corner is the one Johnnie had mounted to his cutting board.

He did some nice work setting in his easy chair.

If anyone is serious about building a stiddy, shoot me a PM & we can arrange to talk by phone.

It is easier to explain than to type it all out.

If you don't want to go to all the work, and it is considerable, you may be able to talk ma into building one.

Dale

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

Re: Got a Question about your bench anvil....

Those are super nice! This area didn't see any of the small rail systems like some areas. In spite of this new stiddy I've got coming, If I ever come across any railroad track I intend to get it (if legal  ). I don't know what the specs are on the metal in them, but they make great anvils of any size.

). I don't know what the specs are on the metal in them, but they make great anvils of any size.

My next trip to the welding shop, I plan to have some of those hardend pieces welded onto those cheap little anvils. Not nearly as nice as Dale's (I love the one is pic # 1005), at 4 bucks eash for the anvils and the metal was free, I figure I can get creative for cheap.

My next trip to the welding shop, I plan to have some of those hardend pieces welded onto those cheap little anvils. Not nearly as nice as Dale's (I love the one is pic # 1005), at 4 bucks eash for the anvils and the metal was free, I figure I can get creative for cheap.

Re: Got a Question about your bench anvil....

Hey Bob,

I don't know about were you Ohio, but in Oregon there are a lot of old railroads around left over from mining and logging operations. I often short pieces at garage sales 1 to 3 feet long. $5 or $10 will usually get you a piece of it. Try your local scrap yard, you should be able to find all you want there at a reasonable price. The only issue might be getting them to cut it, but if you are willing to pay to have it cut they would probably cut it for you.

I don't know about were you Ohio, but in Oregon there are a lot of old railroads around left over from mining and logging operations. I often short pieces at garage sales 1 to 3 feet long. $5 or $10 will usually get you a piece of it. Try your local scrap yard, you should be able to find all you want there at a reasonable price. The only issue might be getting them to cut it, but if you are willing to pay to have it cut they would probably cut it for you.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

Re: Got a Question about your bench anvil....

Elvis talking about working with "crap"......I've never been a stranger to it. My daddy always farmed and after I started getting out from under his wing, I wanted to start getting some of my own stuff. Probably the best "early" purchase I made was I went to Sears and bought a full set of tools (didn't know at the time but these were to be put to much use in the future!!). I started going to auctions every time I got a chance and picked up some used farm equipment. I've always been a frugal person, so when I saw a piece of well used machinery I figured with a little? work it would be just what I needed. For the 1st couple of years my routine was to work on equipment for 2-3 days just to use it 1 day. It didn't take long for me to realize that the guy who first said the famous line.......you get what you pay for, knew what he was talking about! I truly hate to borrow anything and I try to live by the "borrow it more than once, you need one of your own." I never turned anyone down that ever asked to borrow from me though and am still that way. Sometimes you just have to do the best you can with you got and that's the way I am with my pocketknife repair "crap"......I don't try to do anything but for my own use but every so often someone will want me to do something. I get by with the "crap" I use but a cutler stiddy would be VERY nice. I guess it's on my bucket list. When you get yours in, don't forget to post some pics.

- jerryd6818

- Gold Tier

- Posts: 39412

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Got a Question about your bench anvil....

Cope, I just read those old posts on BladeForum yesterday and you're right, Great Lakes Water Jet was making them back about 2007. He started off selling them for $350 but then cut his price down to about $275 for the next batch. Saw some pictures and they looked really nice. I didn't see any recent updates to the thread.Cope wrote:Gary I did find the copies I had run and most of them DID come from bladeforum. The fit and finish on the ones I copied is smooth as silk. It seems that every line runs into another.......like a flow, I guess. I had written down that Great Lakes Water Jet was either making them or going to start making them. I went to their website (unless there is more than one) but didn't see any. When I piddle with knives, I've got my own home made crap that I get by on. When I win the lottery, I've got a stiddy on the list!

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

Re: Got a Question about your bench anvil....

I've got the guy who made this one for me considering making more. IF he decides to do it, I have no idea what he will charge. But anyway, here is the Stiddy (I believe that's what the old timers called them) that I've been waiting months for. A4 tool steel, which I believe is some form of stainless and made exactly to the specs shown on the drawing I posted earlier. I can't wait to mount it to the bench and start using it.

- muskrat man

- Gold Tier

- Posts: 5672

- Joined: Fri Jun 30, 2006 4:04 am

- Location: Ohio

- Contact:

Re: Got a Question about your bench anvil....

Bob, if your friend wants to make another call me, I want one. As for my bench blocks, nuttin too special, I've got a big steel block for doing all kinds of crap on, micarta block for tapping out pins and such on, specially cut wood block for tapping out pivot pins in switchblades, a stiddy horn that I can clamp in my panavise, and one of Dale's stiddys that I use occasionally (too sot in my routine to fully switch over to it from my big flat chunk of steel though it would do most any job quite fine) I also have a tiny little plated anvil that I use for working on jewelery or pen knives.

Custom knives, repair, restoration & embellishment

Certified Hubertus, Taylor, & Schrade repairman past and present

http://www.muskratmanknives.com

https://www.facebook.com/Muskratmanknives

Certified Hubertus, Taylor, & Schrade repairman past and present

http://www.muskratmanknives.com

https://www.facebook.com/Muskratmanknives

- Tom Hudson

- Posts: 218

- Joined: Sat Nov 27, 2010 3:40 am

- Location: Marysville, CA

- Contact:

Re: Got a Question about your bench anvil....

Here's mine - i had it made in about 1987 in Texas. Cost me over 300 bucks back then. It has served me well - as you can see, all the edges are still nice & sharp - Tom

Re: Got a Question about your bench anvil....

Tom, Your's looks like it was made to the same specs as mine. I can see that the pictures of mine give the illusion of something less than straight lines and smooth surfaces. That isn't the case. One difference I can see is that yours is welded on to the base and mine is held on with two large bolts countersunk through the base. Other than that it looks like we may have pulled our plans from the same book.  Would you know what steel it is made from?

Would you know what steel it is made from?

Looking back a page, Orvet's appears to have the same design/dimensions. Have these ever been made comercially?

I hear ya Kaleb. The guy is considering making more. Kind of like a definite maybe. I did some very heavy bartering to get this one. I have no idea what he may charge if he decides to make any more.

Looking back a page, Orvet's appears to have the same design/dimensions. Have these ever been made comercially?

I hear ya Kaleb. The guy is considering making more. Kind of like a definite maybe. I did some very heavy bartering to get this one. I have no idea what he may charge if he decides to make any more.

Re: Got a Question about your bench anvil....

In the case of my first stiddy, yes it were made semi-commercially.Elvis wrote: Looking back a page, Orvet's appears to have the same design/dimensions. Have these ever been made comercially?

A fellow in Canada made a small batch of them, (or had them made).

I think it was a batch of 12 or 18 stiddys.

IIRC, he was the same fellow who made the knife vises out of square steel tubing with the billiard ball handles.

I don't know of anywhere that has stiddys available commercially and in stock.

As you might imagine they are something that probably doesn't fly off the shelf.

They have a specialized use and therefore a very limited niche market.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

Re: Got a Question about your bench anvil....

Anvil Shooting: using explosives to fire anvils -- yes, ANVILS -- into the air.

This doesnt have anything to do with knives but it is about anvils, enjoy the show.

http://boingboing.net/2009/10/20/anvil- ... eviouspost

This doesnt have anything to do with knives but it is about anvils, enjoy the show.

http://boingboing.net/2009/10/20/anvil- ... eviouspost

Re: Got a Question about your bench anvil....

rwd57 wrote:Anvil Shooting: using explosives to fire anvils -- yes, ANVILS -- into the air.

This doesnt have anything to do with knives but it is about anvils, enjoy the show.

http://boingboing.net/2009/10/20/anvil- ... eviouspost

Funny stuff, I have seen video of those shenanigans before.

There was even one where an anvil came down on the tailgate or in the bed of a guy's pickup, IIRC.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

Re: Got a Question about your bench anvil....

Hi all, I have a few steadies for sale and in stock, as advertised in Knife World classifieds. If you have the October 2009 issue, you can see the specs and a pic, or email me for specs and photos at mikeandpat@centurytel.net

It is patterned after the the one found in Ben Kelley's book on P. 19

Mike

It is patterned after the the one found in Ben Kelley's book on P. 19

Mike

Re: Got a Question about your bench anvil....

I had a machinist I know make this one for me, I took him the plan yesterday and he sent me this pic today. I will pick it up tomorrow and post better pictures, he asked me if anyone would be interested in one as he has it programmed into his CNC, I had him make the base seperate and it is held on with 2 machine screws.

- Attachments

-

- steady.jpg (44.53 KiB) Viewed 3857 times

IYAAYAS