Camillus electrican's knife variations

- garddogg56

- Bronze Tier

- Posts: 9537

- Joined: Mon Mar 07, 2011 2:18 am

- Location: Maine Aya up North

Re: Camillus electrican's knife variations

Mtds;Oh those analog meters mines a Tripplett USA,When I was an apprentice we made the kit Simpson meter long gone now I think it took a hit  Yet these kids don't know how good they have it nowadays

Yet these kids don't know how good they have it nowadays  It's getting harder to advoid the imports nowadays

It's getting harder to advoid the imports nowadays

"On the Road Again"Willie Nelson

- orvet

- Gold Tier

- Posts: 19568

- Joined: Tue May 16, 2006 6:23 am

- Location: Willamette Valley, Oregon

Re: Camillus electrican's knife variations

garddogg & mtds, sounds like you both are/were electricians.

You are no doubt familiar with Klein Tools (who had some of their TL-29s made by Camillus and probably others) and their American made hand tools. I have been looking for a small (4-5”) pair of flush-cut end nippers for several years. Most of the ones I find are imported and they don’t make a flush cut version. After years of searching I finally found a flush-cut end nipper made by/for Klein Tools. It is only about twice the price of the import versions. I have to go back and get them, as I didn’t have the cash with me that day.

I guess we still make a few tools here in the USA!

You are no doubt familiar with Klein Tools (who had some of their TL-29s made by Camillus and probably others) and their American made hand tools. I have been looking for a small (4-5”) pair of flush-cut end nippers for several years. Most of the ones I find are imported and they don’t make a flush cut version. After years of searching I finally found a flush-cut end nipper made by/for Klein Tools. It is only about twice the price of the import versions. I have to go back and get them, as I didn’t have the cash with me that day.

I guess we still make a few tools here in the USA!

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

-

Vit_213

- Posts: 1163

- Joined: Sat Dec 10, 2011 6:57 am

- Location: Moscow, Russia

Re: Camillus electrican's knife variations

Another photo.

This is not a chorus line

- garddogg56

- Bronze Tier

- Posts: 9537

- Joined: Mon Mar 07, 2011 2:18 am

- Location: Maine Aya up North

Re: Camillus electrican's knife variations

Dale I believe they are tywire cutters,kinda hard to find Iron workers use them all the time..Vit them legs gutta rest sometime they look good closed

"On the Road Again"Willie Nelson

-

mtds

- Posts: 82

- Joined: Fri Sep 08, 2006 4:59 pm

Re: Camillus electrican's knife variations

Vit_213 wrote:Another photo. This is not a chorus line

Vit_213: Any idea what the scales are made of on the two knives on the right?

- jerryd6818

- Gold Tier

- Posts: 39427

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Camillus electrican's knife variations

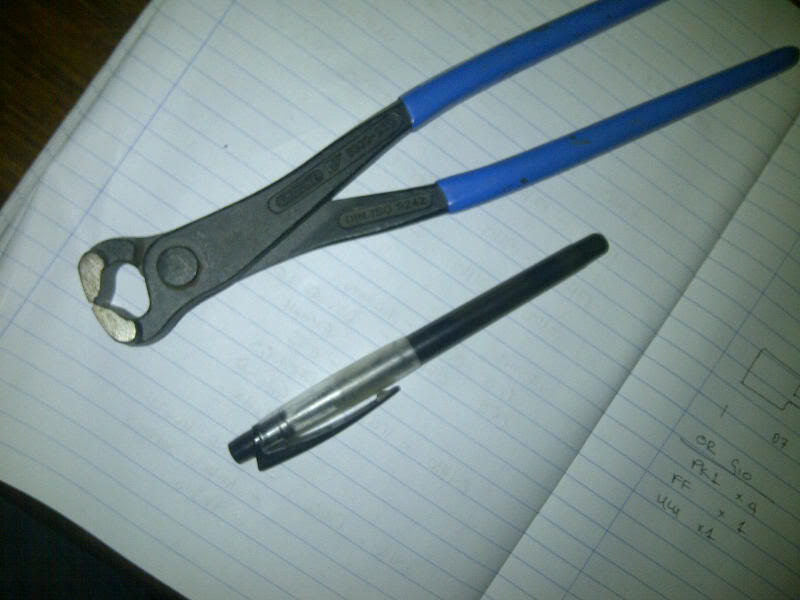

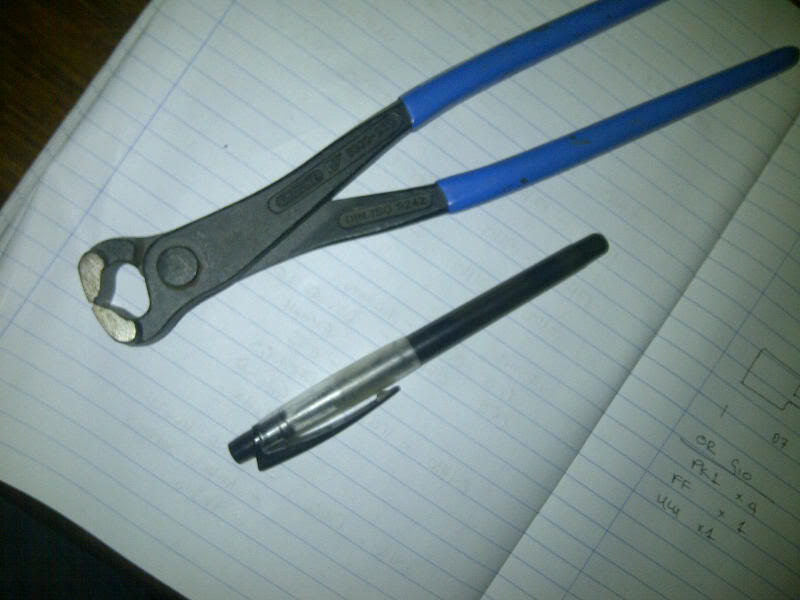

Dale - Are these what you're looking for? These are flush-cutters but you said "end-nippers" which these are not. (shown last below)

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

-

Vit_213

- Posts: 1163

- Joined: Sat Dec 10, 2011 6:57 am

- Location: Moscow, Russia

Re: Camillus electrican's knife variations

Smooth black Delrinmtds wrote:Vit_213 wrote:Another photo. This is not a chorus line

Vit_213: Any idea what the scales are made of on the two knives on the right?

- orvet

- Gold Tier

- Posts: 19568

- Joined: Tue May 16, 2006 6:23 am

- Location: Willamette Valley, Oregon

Re: Camillus electrican's knife variations

That us very close to what I am looking for Jerry.

When assembling a knife and spinning down the rocker pin it is difficult to cut the pin short enough unless one has a flush cutter. If one leaves the pin too long it does not tighten the pin enough to pull the sides of the knife close enough, thereby leaving a gap between the spring and the liners.

With a flush cutting end nipper it is easier to push down on the nipper to push the liners against the spring and then cut the pin to the proper length. The spinner then spins the head slightly into the handle creating a nice tight fit between the spring and liners.

The advantage to the end nipper is that it is easier to push straight down on the nipper to close the gap before cutting the pin. The one you show would be a close second choice, as the angle on the head would allow one to get nearly as much pressure on the handles as would an end nipper.

I hope that makes sense....

When assembling a knife and spinning down the rocker pin it is difficult to cut the pin short enough unless one has a flush cutter. If one leaves the pin too long it does not tighten the pin enough to pull the sides of the knife close enough, thereby leaving a gap between the spring and the liners.

With a flush cutting end nipper it is easier to push down on the nipper to push the liners against the spring and then cut the pin to the proper length. The spinner then spins the head slightly into the handle creating a nice tight fit between the spring and liners.

The advantage to the end nipper is that it is easier to push straight down on the nipper to close the gap before cutting the pin. The one you show would be a close second choice, as the angle on the head would allow one to get nearly as much pressure on the handles as would an end nipper.

I hope that makes sense....

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

- jerryd6818

- Gold Tier

- Posts: 39427

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Camillus electrican's knife variations

It does make sense but these pliers aren't suited for that task. They're designed for electronics work and are not recommended for anything but small soft copper wire, 20ga (.034) and smaller.

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

Dale, is this what you have in mind:

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- garddogg56

- Bronze Tier

- Posts: 9537

- Joined: Mon Mar 07, 2011 2:18 am

- Location: Maine Aya up North

Re: Camillus electrican's knife variations

Smokepole that is what I was thinking we use those to tie rerod togeather but they don't cut flush enough a pair of sidecutter will do the samething

"On the Road Again"Willie Nelson

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

garddogg, I know them as end cutting pliers/end nipps/steel fixers pliers/rigging pliers/riggers pliers etc etc - we also use them over here to for fixing re-enforcing steel cages for concrete etc. You do get some models that cut flush - or if you have a belt sander or nice big wet grinder like Dale has, you could very easily convert the standard model into a flush cutter.

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- orvet

- Gold Tier

- Posts: 19568

- Joined: Tue May 16, 2006 6:23 am

- Location: Willamette Valley, Oregon

Re: Camillus electrican's knife variations

That is the general idea, though I was hoping to find ones that were made for a flush cut.

I think my problem has been solved by Aimus Moses.

Aimus read this thread and PMed me. He is mailing me a pair that he has.

AAPK has the best members on the web!

Thanks Aimus.

I think my problem has been solved by Aimus Moses.

Aimus read this thread and PMed me. He is mailing me a pair that he has.

AAPK has the best members on the web!

Thanks Aimus.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

- jerryd6818

- Gold Tier

- Posts: 39427

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Camillus electrican's knife variations

Well, show 'em when you get 'em. Not that I've seen every pair of pliers ever made but I've not seen any of the end nippers in flush cut. I used to have a set of end cutters that had handles like and were made like the Bernard parallel jaw pliers. I can't find them. We sometimes used them to pull taper pins out of a shaft when we couldn't get a punch on the other end.

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

Jerry, here's some pics of an old pair of flush cutters I have - the jaws and pivot pin are all shot and don't bite flush or in line with each other any more - you can see that in the first pic - the jaw on the right of the pic is at an angle to the other one. The very slight angle you see on the outside of the jaws/cutting edge is something I put there a couple of years ago trying to touch up the cutting edge without stripping the pliers apart - I stopped when I realized it wouldn't cut flush anymore if I carried on any further. I now use it just as a puller - the other pair cuts flush enough for peening and spinning purposes. Looking at it now I reckon I need to take them apart and give them a good reconditioning.

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- jerryd6818

- Gold Tier

- Posts: 39427

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Camillus electrican's knife variations

Thanks for showing those Smoke. They look like they've been around for a while.

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

That they have. Like yourself I hate throwing something away if it has the slightest chance of still being useful - that is why I like making knives out of files and old circular saw blades too. So I reckon a revamp is on the cards for this pair..They look like they've been around for a while.

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- orvet

- Gold Tier

- Posts: 19568

- Joined: Tue May 16, 2006 6:23 am

- Location: Willamette Valley, Oregon

Re: Camillus electrican's knife variations

Speaking of circular saw blades....I have one from a saw mill that is about 4 feet in diameter.

I will have to get some pics later....my wife & I are going garage sale-ing.

I will have to get some pics later....my wife & I are going garage sale-ing.

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

Nice steel that Dale. I'd love to see some pics - as a general rule, if the cutting tips are shaped from the blade steel itself and not tungsten inserts, and the thinner the blade relative to it's diameter, the better the steel. If that blade is between 1/8th and 1/5th thick you have yourself some really nice high carbon steel for knives.

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- zp4ja

- Posts: 4665

- Joined: Tue Mar 13, 2012 9:47 pm

- Location: Northern Nevada

Re: Camillus electrican's knife variations

Good thread Guys. Never visit this forum ( I am a Case collector) but I have found this one in my tool box in great shape.

Looks to be 3-3/4" closed. Stamp in case u cant see it is...

CAMILLUS

________

NEW YORK

U S A

Not spaced or centered like that but you get the idea.

Thanks, Jerry

Looks to be 3-3/4" closed. Stamp in case u cant see it is...

CAMILLUS

________

NEW YORK

U S A

Not spaced or centered like that but you get the idea.

Thanks, Jerry

That man is a success who has lived well, laughed often and loved much; who leaves the world better than he found it; who never lacked appreciation of earth's beauty or failed to express it; who looked for the best in other's and gave the best he had.

- orvet

- Gold Tier

- Posts: 19568

- Joined: Tue May 16, 2006 6:23 am

- Location: Willamette Valley, Oregon

Re: Camillus electrican's knife variations

nice one zp.

Did you know that for many years Camillus built the TL-29 for Case as well as most of the US knife makers?

Did you know that for many years Camillus built the TL-29 for Case as well as most of the US knife makers?

Dale

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

AAPK Administrator

Please visit my AAPK store: www.allaboutpocketknives.com/orvet

Job 13:15

"Buy more ammo!" - Johnnie Fain

“Evil is Powerless If The Good are Unafraid.” – Ronald Reagan

- zp4ja

- Posts: 4665

- Joined: Tue Mar 13, 2012 9:47 pm

- Location: Northern Nevada

Re: Camillus electrican's knife variations

No Sir Dale, I did not.

What do you know about the one I posted as far as year/era goes. Just curious how old she is.

Thanks for the input, Jerry

What do you know about the one I posted as far as year/era goes. Just curious how old she is.

Thanks for the input, Jerry

That man is a success who has lived well, laughed often and loved much; who leaves the world better than he found it; who never lacked appreciation of earth's beauty or failed to express it; who looked for the best in other's and gave the best he had.

- jerryd6818

- Gold Tier

- Posts: 39427

- Joined: Sun Jan 04, 2009 5:23 am

- Location: Farther down the road.

Re: Camillus electrican's knife variations

Long line Camillus -- Not guaranteed but generally accepted years of mfg 1960-1976

Forged on the anvil of discipline.

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

The Few. The Proud.

Jerry D.

This country has become more about sub-groups than about it's unity as a nation.

"The #72 pattern has got to be pretty close to the perfect knife."

--T.J. Murphy 2012

- zp4ja

- Posts: 4665

- Joined: Tue Mar 13, 2012 9:47 pm

- Location: Northern Nevada

Re: Camillus electrican's knife variations

Thanks JerryD! Looking at it closer, this knife has factory edge. Never been put to work. Besides some very minor handles scratches, mint.jerryd6818 wrote:Long line Camillus -- Not guaranteed but generally accepted years of mfg 1960-1976

That man is a success who has lived well, laughed often and loved much; who leaves the world better than he found it; who never lacked appreciation of earth's beauty or failed to express it; who looked for the best in other's and gave the best he had.

- smokepole

- Posts: 326

- Joined: Mon Aug 15, 2011 2:49 pm

Re: Camillus electrican's knife variations

zp4ja, that is a fine example - one of the nicest ones I have seen around. Very handy tools too.

"The true measure of a man is how he treats someone who can do him absolutely no good."

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb

- Samuel Johnson (1709-1784)

Be on your guard against a silent dog and still water.

Latin Proverb