I received a PM asking what rods my welding guy uses and I had to plead ignorance. He asks me if he's welding stainless or carbon steel and takes it from there. The welds don't seem that much harder than the rest of the tang, but without proper testing, it's hard to know for sure. In this case since the tang and backspring were both welded I think it's safe to assume they now have the same hardness in that spot so uneven wear shouldn't be a factor.

As for your welding guy Kaleb, the person who sent me the PM mentioned certain rods that produce a welding bead that is around RC 58. Since modern (factory) blade heat treating methods leave the tang a tad softer than the blade area, I'm wondering if 58 would be too hard and begin to wear on the backspring. I'd also like to mention that he is always careful to clamp the blade or backspring in a vise with only the part that needs attention sticking up. This allows the vise to act as a heat-sink helping to prevent heat transfer to the blade area so we don't lose temper.

This method has worked well for me and is the only way I've found to correct this problem short of using new parts which often just aren't available on a lot of the older knives. Your biggest hurdle in using this method will most likely be finding a welder with the talent and patience to do it. I highly recommend bribery with folding cutlery.

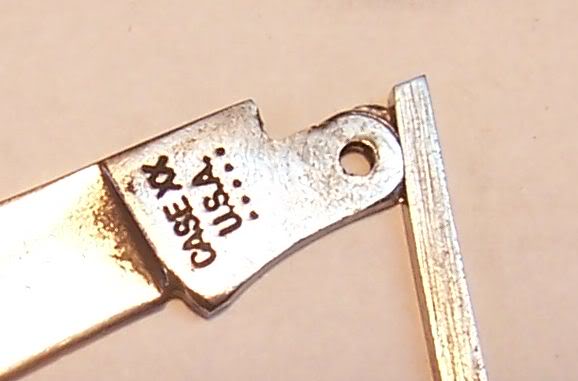

Edited to add that the knife has been reassembled and just looks like the last pictures of it with the pins peined. End of lesson I suppose, but I'll be here for questions and I hope this has been helpful to someone.