Stag Geometry, And How It Affects A Knife's Handle

Posted: Thu Jan 12, 2012 9:58 pm

I recently discussed this with a regular client and got to thinking that others may find value in this as well. Many people don't understand how the various qualities of a set of stag handle slabs can affect the outcome of the finished product. Generally the wider and flatter the better. I see so many knives with the majority of the stag's "bark" or "texture" obliterated because of lack of knowledge of thinning these slabs to the fullest extent from the bottom and preserving all the natural aspects of the stag and they end up with a handle 3-4 times thicker than that of the bolster thickness.

I owe thanks to Charlie Campagna (AAPK member "upnorth") for opening my eyes early on in my career to the superior look, feel, and pocket friendlyness of what he calls "Sheffield stag". The old time Sheffield cutlers used to thin their stag from the bottom allowing the texture and "bark" to run from end to end with little molestation to the stag's original look and texture. These comparison photos and captions will help to explain my point. If you have any questions regarding this, feel free to ask.

If you have knives customized or even customize knives yourself and are considering stag for your next project; take into consideration what you want that knife's handle to look and feel like after the work is complete. Choosing proper stag is a key choice in making the most of your knife and your money. Not only does it make a nicer looking knife in your pocket or collection but being clear on handle preference makes the work much easier on the cutler who is doing it.

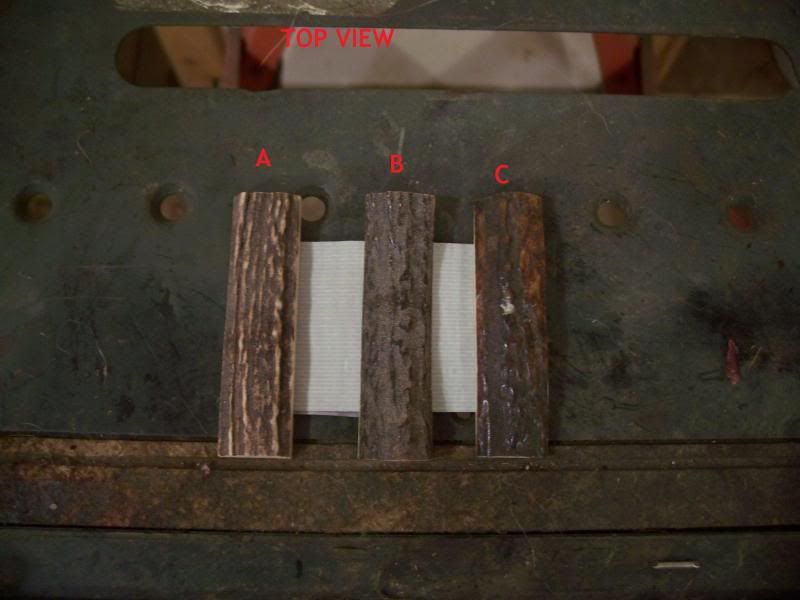

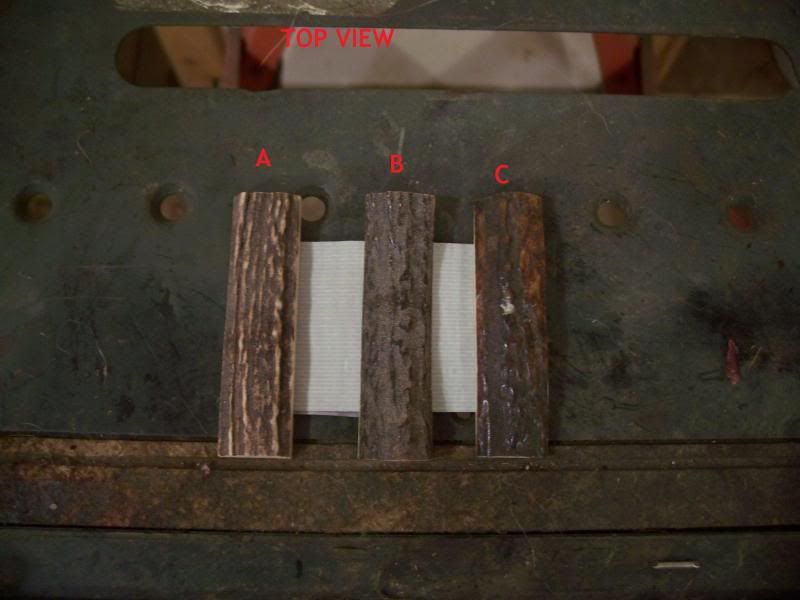

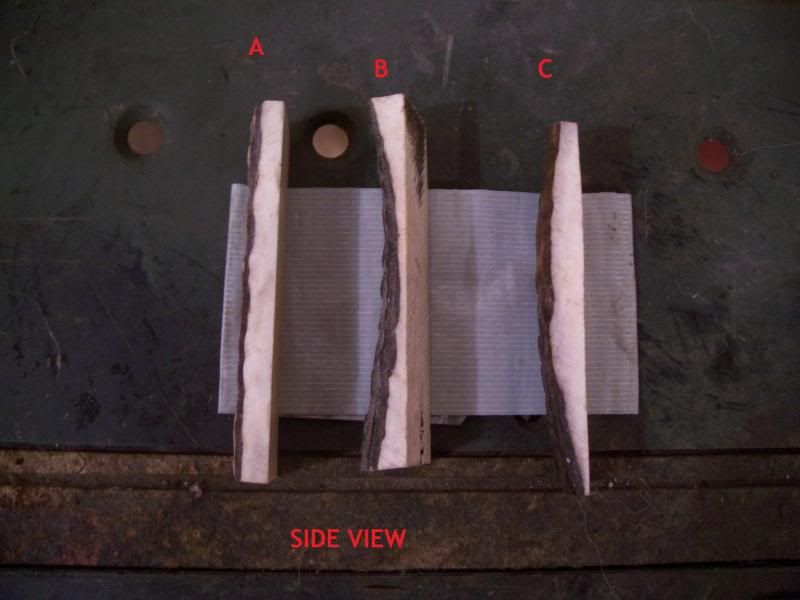

We have 3 pieces of stag A, B and C all look good, right?

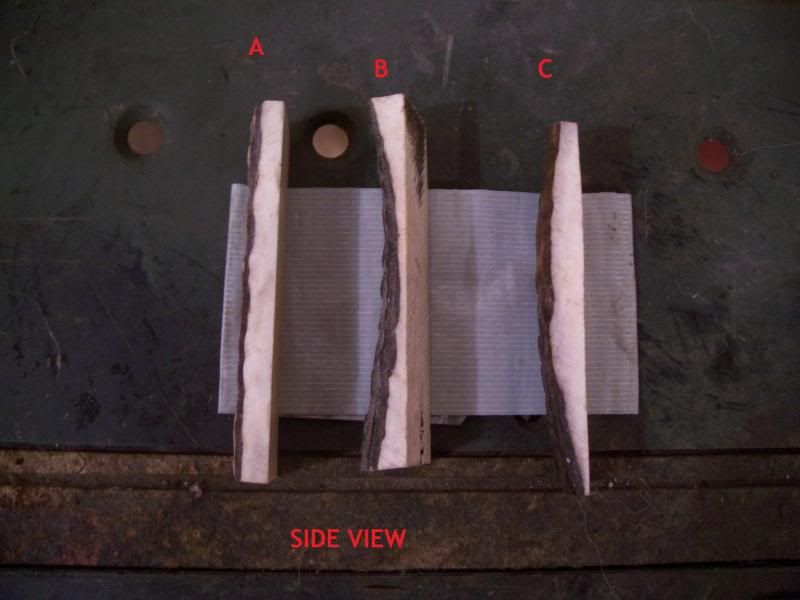

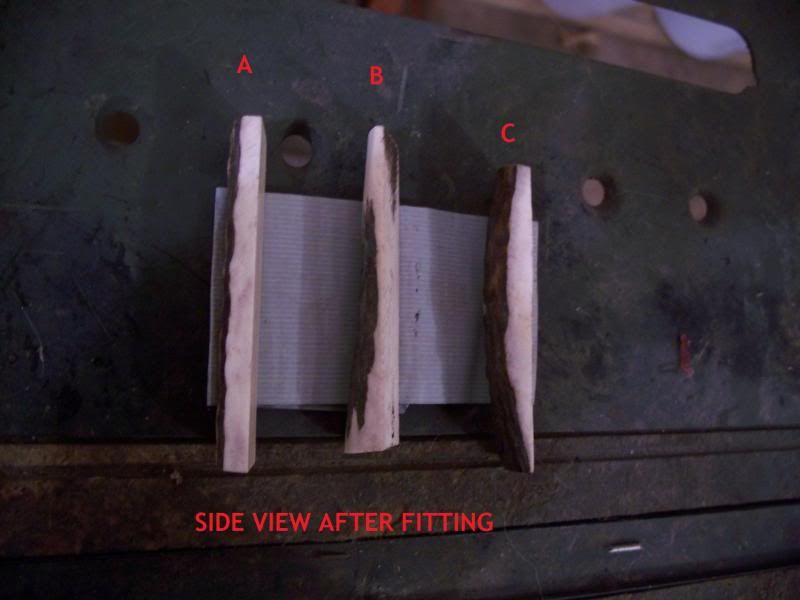

Here are the same pieces turned on edge. A) The best slab to have. It has uniform thickness throughout it's length. B) what I call "swayed stag". C) What I call bulged stag.

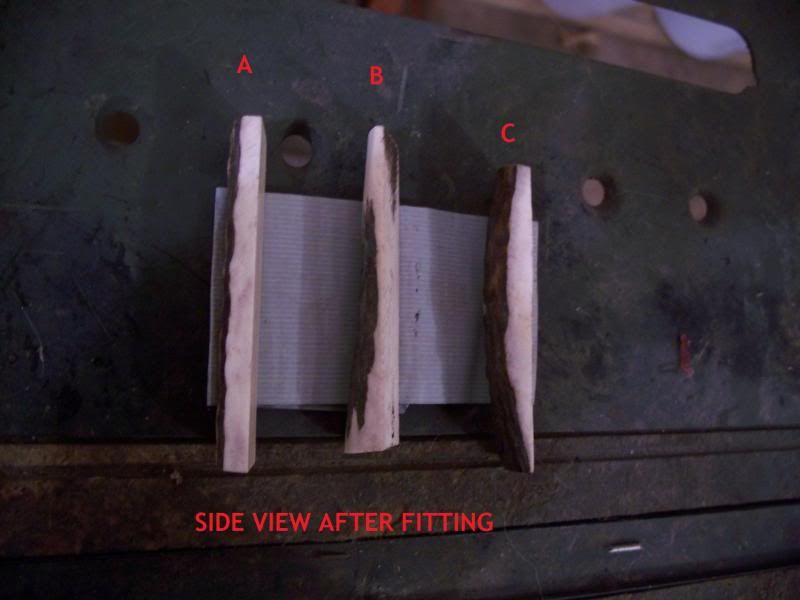

Now providing thickness and width is correct and suitable, slab (A) will be fit from the bottom side to lose as little texture as possible and a nice uniform thickness set of handles will result. Although (B) will have to be cut from one end (on the bark side) to fit the bolster ending in a highly tapered handle with general loss of 1/3 to 1/2 of the texture. If the knife hans bolsters on either end you will end up with a flat handle but a very small amount of texture in the very center surrounded by hafted smooth white areas where all the bark had to be removed to fit the thickness of the bolsters. Lastly, (C) will also be fit from the bottom until the ends meet the thickness of the bolsters (providing thickness and width is correct) but the center of the handle will be MUCH thicker creating a "bulged" handle.

In the end this is what you'll have at the butt end of your knife if it is of a barehead design.

I owe thanks to Charlie Campagna (AAPK member "upnorth") for opening my eyes early on in my career to the superior look, feel, and pocket friendlyness of what he calls "Sheffield stag". The old time Sheffield cutlers used to thin their stag from the bottom allowing the texture and "bark" to run from end to end with little molestation to the stag's original look and texture. These comparison photos and captions will help to explain my point. If you have any questions regarding this, feel free to ask.

If you have knives customized or even customize knives yourself and are considering stag for your next project; take into consideration what you want that knife's handle to look and feel like after the work is complete. Choosing proper stag is a key choice in making the most of your knife and your money. Not only does it make a nicer looking knife in your pocket or collection but being clear on handle preference makes the work much easier on the cutler who is doing it.

We have 3 pieces of stag A, B and C all look good, right?

Here are the same pieces turned on edge. A) The best slab to have. It has uniform thickness throughout it's length. B) what I call "swayed stag". C) What I call bulged stag.

Now providing thickness and width is correct and suitable, slab (A) will be fit from the bottom side to lose as little texture as possible and a nice uniform thickness set of handles will result. Although (B) will have to be cut from one end (on the bark side) to fit the bolster ending in a highly tapered handle with general loss of 1/3 to 1/2 of the texture. If the knife hans bolsters on either end you will end up with a flat handle but a very small amount of texture in the very center surrounded by hafted smooth white areas where all the bark had to be removed to fit the thickness of the bolsters. Lastly, (C) will also be fit from the bottom until the ends meet the thickness of the bolsters (providing thickness and width is correct) but the center of the handle will be MUCH thicker creating a "bulged" handle.

In the end this is what you'll have at the butt end of your knife if it is of a barehead design.