I have done this many times (see pics below) with great success.

You will need to buy some super fine Micro mesh abbrasive paper and use it by hand. This is Jewelry grade cloth backed abrasive used for removing scratches in glass etc.

I use different grades and start with the rougher grades depending on how bad the ding or mark is. The roughest I would recommend using for any mark is 800 grade.

Before doing anything use some masking tape and tape off areas you do not want to remove finish from. Then clean your knife either with 6000 grade mesh or use preferably Jewelry grade polish (dont get it on etching etc) This is very important, you wont be able to see all the marks on your knife unless it is cleaned from oxidation.

Then put it under light and go over it to see what marks and how deep they are.

The deeper the marks are the courser grade mesh you will have to use and this will mean it is going to take much longer because the courser grade mesh will leave scratches that will need to be removed latter.

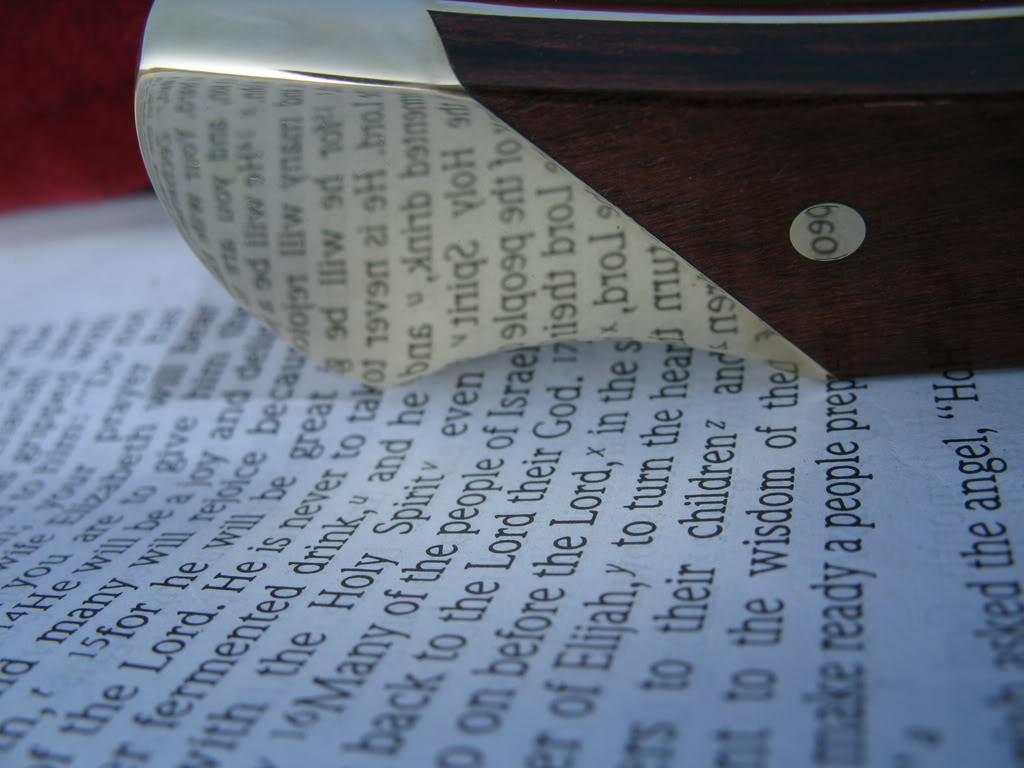

Make a work area and sit knife on soft cloth on table. First try and see if the marks will come out with a finer mesh like 3200 grade 2000 grade or 1500.If no success and the marks are deep you will have to use 800. Cut lots of small peices (as in pic) you will notice that the mesh clogs quickly with the brass or nickel so use lots peices in quick succession this will save you time.

If you have to go to 800 to remove marks you will need to then use 1200 to remove the light scratches that the 800 caused. Next 1500 then 2000 each one improves the last. 3200, 4000 and then lastly 6000.

These are the only grades I tend to use and there are some wide gaps between them (4000 to 6000). A way around this is just before using the 6000 grit use the 4000 with a peice that is a little glogged it will act a little similar to a 5000 grit.

If you do it right the finished result is simply stunning. You should easily be able to see your reflection in the completed area.

Below are some of my projects, see lens in pic.

The Micro Mesh abrasive usually has a cloth packing so you can wash and re-use it. Anything up to around 2000 grit should be able to be purchased from a car auto paint supplier and is usually paper backed and much cheaper, I use both paper backed and cloth backed for this reason.

Oh and lastly be careful you dont cut your fingers and if in doupt practise on an old cheap knife first.

Additional Note: Recently I have used the cutting paste below for getting an incredible mirror finish on some of my blades. It the best product I have used so far. You could probably use a little less of the sheets of abrasive and this instead, it is excellent. I used a powerful drill with a buffer held between my knees while standing. I dont recommend holding it this way as its unsafe. Be careful to hold the blade on the buffing wheel so as not to dull the edge of the blade. It will dull the edge a little but can be re-sharpened easily. I purchased the paste from and Auto paints store Ive tried cheap repco cutting compound with no or little effect this large tube below was $26 AUD & well worth it.

If you decide to polish a blade then please appreciate the difference in the amount of work required to polish to a Mirror finish a standard Brushed metal semi gloss blade and one that already has a smooth high gloss finish.

Regards Tim

[/IMG]

[/IMG]